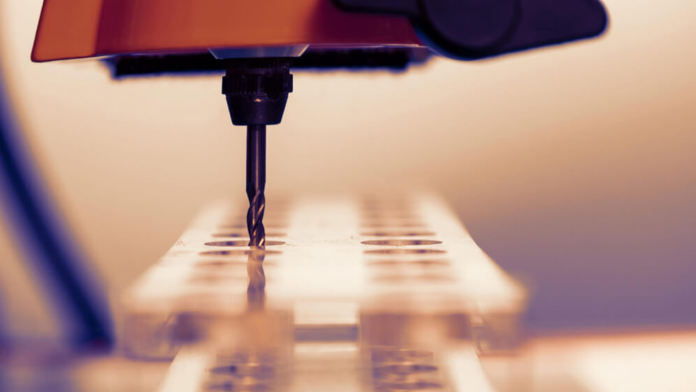

Polymer Computer Numerical Control (CNC) machining is the process of precisely shaping and cutting plastic materials using CNC machines. Computer-aided design (CAD) software is used in CNC machining to produce instructions that direct the CNC machine to produce intricate and precise plastic components.

A solid block or sheet of plastic, such as polyethylene, nylon, or acrylic, is usually the first step in the process. It is then fastened to the CNC machine. The machine’s cutting tools shape, mill, or drill the plastic to the required shape and size using computerized instructions. In numerous industries, plastics machining is extensively employed to create intricate plastic parts, prototypes, and customized pieces with unmatched precision.

Which Plastic is Most Frequently Used in CNC Machining?

Polymethyl methacrylate, or acrylic, is a frequently utilized plastic in computer numerical control (CNC) machining. Its favorable machining qualities, which include ease of drilling, turning, and milling, account for its widespread popularity. Excellent clarity, a smooth surface, and dimensional stability make acrylic the perfect material for applications that call for translucent or transparent parts.

It also shows good durability and chemical resistance. Nylon, Delrin (acetal), polyethylene, and polycarbonate are additional polymers that are frequently machined using CNC techniques. These materials are selected based on particular application needs, such as mechanical strength, heat resistance, or electrical insulation.

Some Typical Uses for CNC Machining in Plastic

Computer numerical control (CNC) machines are used in the plastic CNC machining process to precisely and intricately shape and cut plastic materials. This technique is appropriate for a multitude of applications due to its many benefits. Typical uses for plastic CNC machining include the following:

Prototyping and Rapid Tooling:

The process of rapid prototyping is one of the main uses for plastic CNC machining. With the use of CNC machines, engineers and designers can produce tangible prototypes from digital designs much more quickly, allowing for quicker iterations and a shorter time to market. Furthermore, a lot of CNC machining goes into making injection molding molds, which speeds up the large-scale, quick production of plastic components.

Automotive Components:

Plastic CNC machining is a major production method used in the automotive industry. CNC machining guarantees accuracy and consistency in the manufacturing process for both external and interior components, such as grilles and light housings, as well as dashboard components and knobs. Automotive parts can be made to be both robust and lightweight thanks to the versatility of plastics.

Medical Devices:

Plastic CNC machining is essential to the manufacturing of components for medical devices, as accuracy is of the utmost importance in this field. Medical device quality is ensured by CNC machining, which is used in the production of complex surgical instruments and diagnostic equipment casings that meet exacting standards. Certain plastics are also suitable for a variety of medical applications due to their biocompatibility.

Consumer Goods and Electronics:

Plastic CNC machining is very beneficial to the electronics sector, as it is necessary to create precise parts like panels, connectors, and housings. Plastic CNC-machined components are also found in consumer goods like laptops, cellphones, and home appliances, demonstrating the versatility and effectiveness of the technology in mass production.

Aerospace Applications:

Plastic CNC machining is used to make strong, lightweight components in the aerospace industry, where weight reduction and high-performance materials are essential. CNC machining guarantees that aerospace components, from structural elements to interior fittings, meet strict safety and performance standards.

Customization in Design:

Using plastic CNC machining, complex and customized designs are possible that would be difficult or impossible to accomplish using conventional manufacturing techniques. This degree of personalization is especially useful in sectors like fashion, where distinctive and visually beautiful plastic parts can be manufactured precisely and reliably.

Conclusion

A crucial part of modern manufacturing is plastic CNC machining, which provides precision and versatility to a variety of industries, such as aerospace, automotive, and medical. Its ability to produce lightweight components, speed up rapid prototyping, and create intricate designs highlights its critical role in shaping the future of various manufacturing sectors.