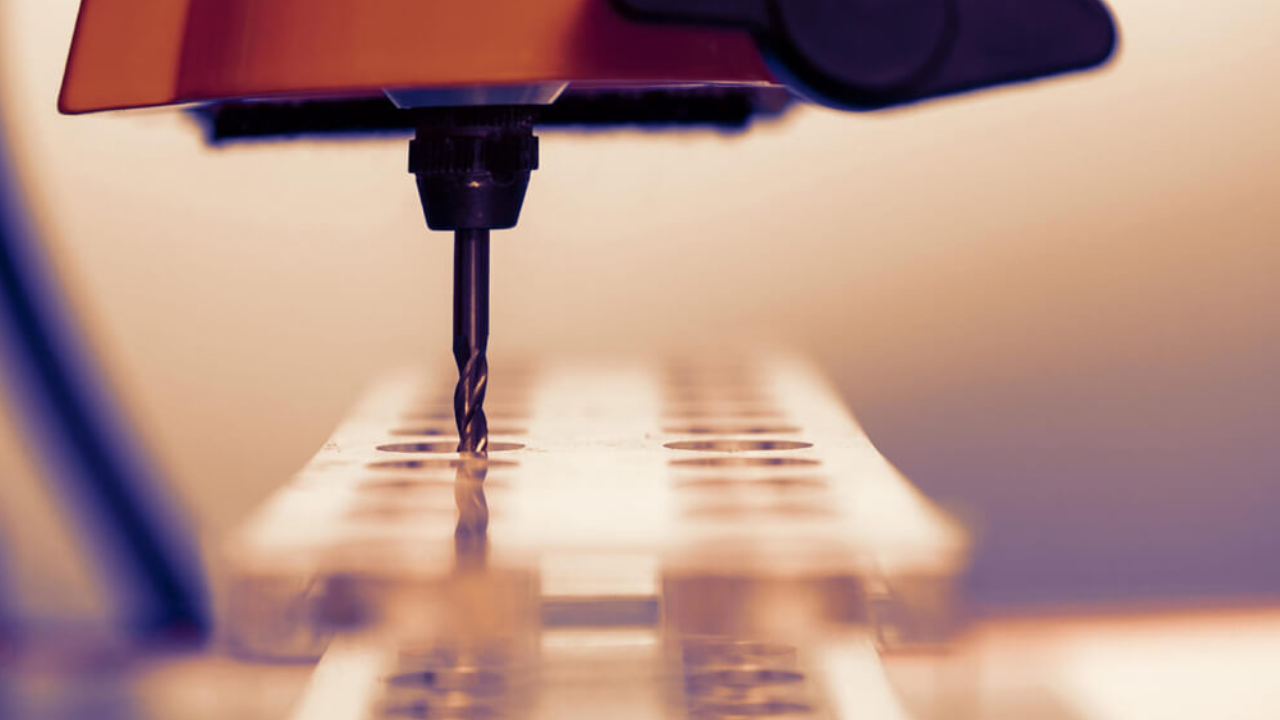

Looking at cnc macined objects will make you appreciate technology more than you ever had. Technology has grown over the years in a bid to make life easier and make pr3ocesses more accurate. If you were to use most machines, you need to handle the device before it can work. For instance, a drilling machine will start drilling unless you press the button necessary for the drilling. Also, this drilling machine will not stop working unless you control it to stop. So while it is a machine, it still relies on your input for any operation. Maintaining the machine is still faster, easier, and better than using the device, but it is not the machine’s primary purpose. In most cases, you want ease while using a machine.

A CNC machine, otherwise known as a computer numerically controlled machine needs little to no input on your end. This machine works with two main segments computer aided design(CAD) and computer aided manufacturing (CAM). Designing on a computer is an easy job that assures you of accuracy. However, implementing these designs is almost impossible to do without mistakes. A CNC machine doesn’t rely on you but the machine. Therefore, the machine reduces the chances of human errors. Also, it promises you computer accuracy. After the computer designs the item, it goes ahead to manufacture the object without needing your input. There is a lot of good things about the CNC machine. However, there are also some bad things about this device. In this guide, we will focus on some disadvantages of these machines. Some of these include;

High cost to buy the machine

CNC machines are unique – no doubts about that! Because of the amazing features of these machines, you will need a high capital to buy one. CNC machines come in different types, each having its respective components. The price of a CNC machine depends on the features of the device. If you have a flexible device that can perform many things, you may pay very high for the machine.

High cost to install the machine

Buying a CNC machine is one thing; installing is a different process. CNC machines are not one of those machines you purchase and take home to use on your own. Even with the user manual, you need a professional to install the machine properly to ensure optimum performance. This processional will charge installation costs.

High cost to replace machine parts

A CNC machine can work for as long as you need it to work. But like every other machine, this machine is bound to have damages over time. Mainly, some of these damages may require a total replacement of some parts. The parts of CNC machines are not commonly found in the market, making them pricey. In most cases, you’ll need to meet a CNC machine manufacturer to make the part for you.

Requires an expert

After you have bought and installed your CNC machine, you may think that is the end of your transactions. But a CNC machine requires a professional to handle it properly. Therefore, it’s either you go ahead to learn about using the machine (which isn’t always free) or you hire a pro. Either ways, you are paying extra.