Achieving a homogenous and consistent blend of various materials is paramount for ensuring product quality in numerous manufacturing processes. Effective mixing processes are crucial for manufacturing plastics, food products, pharmaceuticals, and chemicals.

Gravimetric batch blenders from Yushine offer a precise and reliable solution for blending multiple bulk solids in controlled batches. This article discusses the key benefits of gravimetric batch blenders and addresses potential challenges associated with batch blending operations, along with solutions to overcome them.

What is a Gravimetric Batch Blender

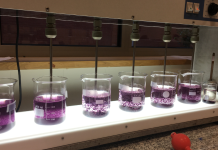

A Gravimetric Batch Blender is a precision mixing device used in industrial settings to blend multiple materials in predetermined ratios based on weight measurements. It utilizes a sophisticated weighing system to accurately measure and combine predetermined quantities of multiple bulk solids.

Gravimetric batch blenders are commonly utilized in industries such as plastics manufacturing, food processing, pharmaceuticals, and chemical production, where precise material mixing is critical for achieving desired product specifications and quality standards.

Benefits of Gravimetric Batch Blenders

Gravimetric batch blenders provide several advantages that contribute to optimized material mixing and quality output:

Enhanced Precision and Accuracy

Gravimetric batch blenders ensure precise material mixing by measuring components based on weight. This method offers superior accuracy compared to volumetric blending and results in consistent product quality and uniformity.

Optimized Material Ratios

Gravimetric batch blenders allow operators to achieve optimal blend ratios by precisely measuring material quantities. This optimization minimizes material waste and consistently meets the desired product specifications.

Versatility in Material Handling

Gravimetric batch blenders can handle a wide range of materials, including powders, pellets, and additives. This versatility enables manufacturers to create customized blends tailored to specific application requirements.

Real-Time Monitoring and Control

With advanced control systems, gravimetric batch blenders provide real-time monitoring of material mixing parameters. Operators can adjust blending parameters on the fly by ensuring optimal performance and quickly responding to changes in production needs.

Challenges and Solutions in Batch Blending Operations

While gravimetric batch blenders offer numerous benefits, some challenges can arise in batch blending operations:

Material Flowability

Poor flowability of certain materials can lead to bridging or segregation within the blender. This hinders accurate measurement and mixing. Solutions may include employing blender designs with agitators or vibrators to promote material flow or using pre-conditioning techniques to improve material handling properties.

Equipment Maintenance

Maintaining gravimetric batch blenders requires regular calibration and maintenance to ensure accurate blending performance. Manufacturers can address this challenge by adhering to a comprehensive maintenance schedule and conducting routine inspections to promptly identify and address any potential issues.

Accurate Weighing

Maintaining the accuracy of the weighing system is crucial. Regular calibration is essential for potential wear and tear or environmental factors affecting weight readings.

Blending Time Optimization

Achieving a homogenous blend requires sufficient mixing time. However, excessive mixing can lead to material degradation. Finding the optimal blending time for each recipe is crucial. Yushine’s blenders can have mixing timers and controls to ensure efficient and optimal mixing cycles.

Final Takeaways

A Gravimetric Batch Blender is a precision mixing device used in industrial settings to blend multiple materials in predetermined ratios based on weight measurements. Their ability to accurately measure and control material ratios translates to significant industry advantages.

Manufacturers can ensure optimal blending performance and achieve consistent quality output by understanding potential challenges and implementing appropriate solutions. Yushine offers a wide range of gravimetric batch blenders to meet diverse needs.